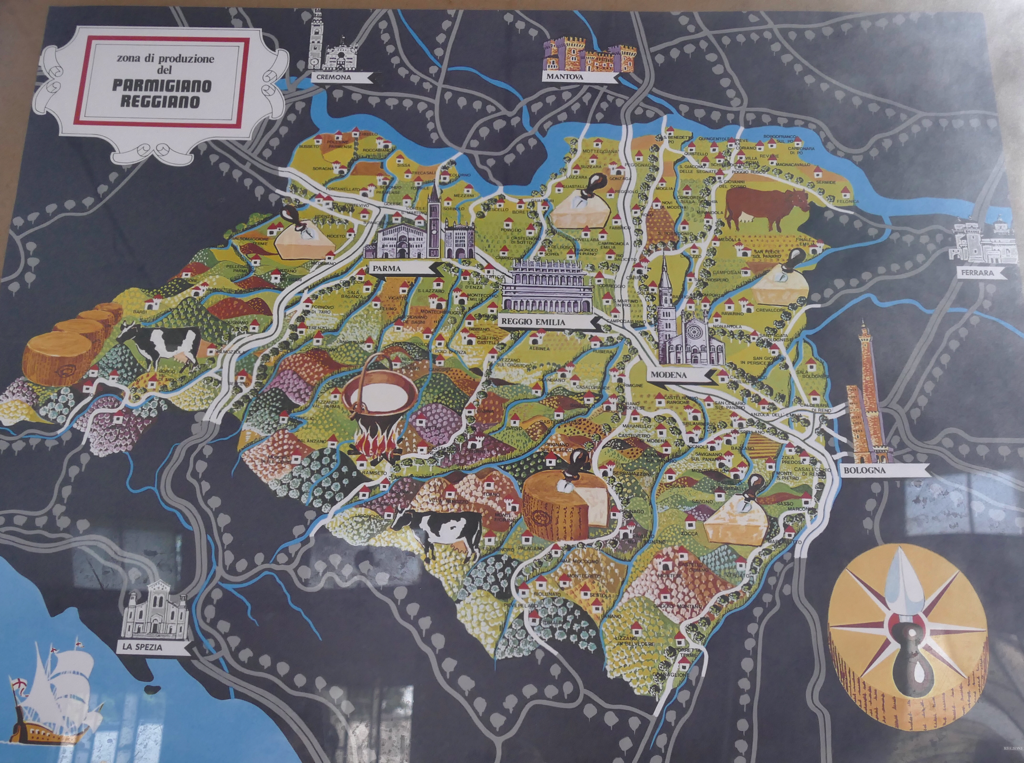

Bologna to Parma, Italy

1 Comment

Ken Bailey

5/3/2016 04:18:07 am

Really interesting . Not quite like a visit to Tillamook.

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Author

Grace and Paul Pitzer are retired school teachers who love to travel and share their stories and photos with others. Archives

October 2019

Categories |

RSS Feed

RSS Feed